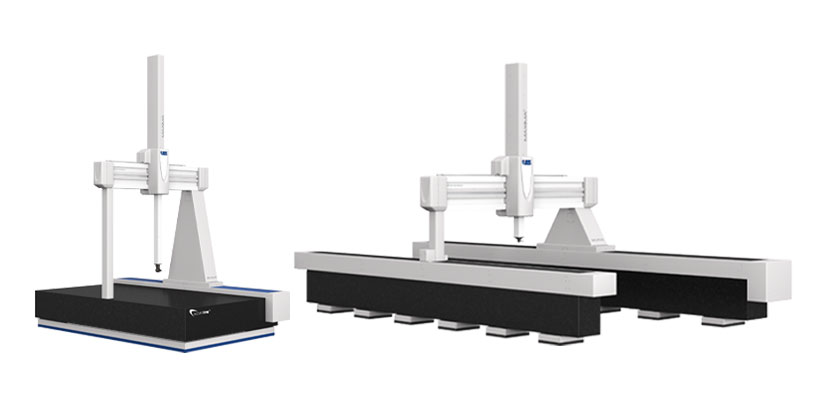

BRIDGE CMM

The Bridge product family’s bridge and quill design provide a thermally stable and ultra-stiff structure for long lasting accuracy and structural stability. This makes our multi-sensor ready, pneumatically-raised CMMs some of the most accurate and durable CMMs on the market.

ALTO

Ultra-Compact Aluminium CMM

Optimised for the new challenges of dimensional quality control, where parts are becoming smaller, designs more complex and design limits are narrowing, the ALTO is ideal for quality professionals taking their first steps in building up an automated inspection capability, with easy-to-use software and versatile options.

ALTO is a compact CMM with space-saving features such as the half-gantry design, fully integrated electronics and retracting monitor arm, making ALTO the perfect fit where space is limited.

Supplied with automated stylus changing as standard, ALTO is available with a standard motorised indexing probe head, or the latest high-performance 5-axis probe system for maximum efficiency. With access from 3 sides for part loading, ALTO is ideal for production areas or quality control rooms.

Additionally ALTO employs high-tech aluminium alloy for the structure and guideways of its moving half-gantry. This cost-effective materials technology provides the stiffness needed for accuracy, while keeping ALTO’s moving mass to a minimum for high-speed measurement.

- Aluminium half-gantry design with micro-machined guideways for precision and hard anodization for resistance to wear and corrosion

- Air bearings with large bearing spread for dynamic stability and a low maintenance, self-cleaning design

- Smooth, exact motion control friction drives enabling zero hysteresis, low maintenance

- 0.1µm encoders – high resolution optical scale system for accuracy

- Optional manufacturing environment-friendly anti-vibration features

- Temperature compensation for quality labs and workshop environments

- Integrated screen and keyboard arm and optional controller mounting

Sizes Available (mm)

| 6.5.5 |

Accuracy

| Volumetric Accuracy | From 2.5+3.0L/1000 |

| Repeatability | From 2.3 µm |

| Velocity | From 500 mm/sec |

| Acceleration | From 1500 mm/sec2 |

Probing Options

Tactile Probes

|

|

Multi-sensor

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

ALTERA C

Compact CMM – Perfect

for smaller spaces

The ALTERA C range of space-efficient ceramic-bridge CMM uses the latest metrology software, multi-sensor technology and design, offering high accuracy measurement and efficient throughput for measurement tasks in quality laboratories and shopfloor environments.

- Compact footprint

- High accuracy measurement and efficient throughput

- Integrated technology with optional monitor & keyboard

Sizes Available (mm)

| 7.7.5 | 10.7.7 | 12.9.7 |

| 10.7.5 | 15.9.7 |

Accuracy

| Volumetric Accuracy | From 1.7 µm + L/333 |

| Repeatability | From 1.5 µm |

| Velocity | From 722 mm/s |

| Acceleration | From 1,903 mm/s2 |

Probing Options

Tactile Probes

|

|

|

|

Multi-sensor

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

ALTERA S

Premium multipurpose CMM with the most advanced capabilities in its class

The ALTERA S’s advanced multi-sensor ready technology optimizes CMM throughput and provides the opportunity to broaden the application scope to new materials and components as needs change, without additional wiring or controllers.

The ALTERA S’s ceramic design, stiffness-to-weight ratio and temperature resistance ensures a high-precision and durability.

- Cutting-edge design built for flexibility

- Advanced multi-sensor ready technology

- Innovative folding guideway panel design

Sizes Available (mm)

| 7.5.5 | 8.7.6 | 10.10.8 |

| 10.7.6 | 12.10.8 | |

| 15.7.6 | 15.10.8 | |

| 20.10.8 |

Accuracy

| Volumetric Accuracy | From 1.8 µm + L/400 |

| Repeatability | From 1.7 µm |

| Velocity | From 762 mm/s |

| Acceleration | From 2,306 mm/s2 |

Probing Options

Tactile Probes

|

|

Multi-sensor

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

ALTERA M

High-speed tactile probe & laser scanning Mid-Size Bridge CMM

Very high accuracy multipurpose, multi-sensor ready CMM with optimized throughput. Like many of the CMMs in the ALTERA family, the ALTERA M is flexible in terms of application scope, materials and components allowing the CMM to adapt easily to changing needs.

The ALTERA M’s size, ceramic design, stiffness-to-weight ratio and temperature resistance ensure rapid, high-precision and durable metrology tasks as required by medical equipment, automotive and aerospace manufacturers.

- Designed for high-speed tactile probe & laser scanning applications

- Wide range of sizes available

- Preferred choice for automotive & aerospace OEMs

Sizes Available (mm)

| 7.5.5 | 8.7.6 | 10.10.8 |

| 10.7.6 | 12.10.8 | |

| 15.7.6 | 15.10.8 | |

| 20.10.8 |

Accuracy

| Volumetric Accuracy | From 1.8 µm + L/400 |

| Repeatability | From 1.7 µm |

| Velocity | From 762 mm/s |

| Acceleration | From 2,306 mm/s2 |

Probing Options

Tactile Probes

|

Multi-sensor

|

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

ALTERA SCANtek5

5-axis multi-sensor CMM for Speed & Flexibility

Powered by REVO, MODUS and dedicated sensors for contact, non-contact and surface finish scanning, the ALTERA SCANtek5 system offers very high throughput as required in automotive and aerospace component manufacturing.

The ALTERA SCANtek5 CMMs feature very high accuracy 5-axis multi-sensors ensuring flexible head positioning and rapid scanning.

- Revolutionary 5-Axis multi-sensor technology

- Ultra fast scanning

- Infinite head positioning

- Surface finish analysis

Sizes Available (mm)

ALTERA M & ALTERA SL sizes available upon request

Accuracy

| Volumetric Accuracy | From 1.5 µm + L/375 (ALTERA M) | From 1.5 µm + L/400 (ALTERA SL) |

| Repeatability | From 1.5 µm (ALTERA M) | From 0.7 µm (ALTERA SL) |

| Velocity | From 833 mm/s (ALTERA M) | From 318 mm/s (ALTERA SL) |

| Acceleration | From 1,676 mm/s2 (ALTERA M) | From 566 mm/s2 (ALTERA SL) |

Probing Options

Multi-sensor

|

Laser Scanning

|

|

|

|

ALTERA SL

Sub-micron accuracy, speed and market-leading flexibility

LK Metrology’s most advanced high-accuracy CMM, the ALTERA SL features multi-sensor ready technology, ultrafast dynamics/raised shoulders, optional sub-micron precision, increased stiffness, stability, and rapid throughput.

- SL series is the most advanced high accuracy CMM LK offers

- Innovative short-leg bridge design

- High Accuracy version achieves sub-micron accuracy

Sizes Available (mm)

ALTERA SL

| 8.7.6 | 10.10.8 | 15.12.10 | 25.15.10 | 20.15.15 | 25.20.15 |

| 10.7.6 | 15.10.8 | 20.12.10 | 25.15.15 | ||

| 15.7.6 | 20.10.8 | 25.12.10 | |||

| 25.10.8 |

ALTERA SLHA

| 8.7.6 | 10.10.8 | 15.12.10 |

| 10.7.6 | 15.10.8 | 20.12.10 |

| 15.7.6 | 20.10.8 | 25.12.10 |

| 25.10.8 |

Accuracy

| Volumetric Accuracy | From 1.1 µm + L/400 (ALTERA SL) | From 0.7 µm + L/600 (ALTERA SLHA) |

| Repeatability | From 0.7 µm (ALTERA SL) | From 0.5 µm (ALTERA SLHA) |

| Velocity | From 850 mm/s (ALTERA SL) | From 317 mm/s (ALTERA SLHA) |

| Acceleration | From 1,407 mm/s2 (ALTERA SL) | From 566 mm/s2 (ALTERA SLHA) |

Probing Options

Multi-sensor

|

|

Scanning

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

MAXIMA

Proven pedigree with large-scale applications

The Maxima range of solutions has a proven pedigree within aerospace, large-scale commercial vehicle applications and manufacturers of large performance critical components.

The unique LK Metrology, proprietary design, low gap high efficiency air bearings and zero hysteresis drive systems ensure premium quality, high accuracy and throughput of Maxima CMMs to meet the needs of large-scale manufacturers.

- Very large-scale metrology applications

- Bonded ceramic materials

- High performing beam and spindle construction

- Greater resistance to time, wear and temperature variations

- Touch-trigger, contact and non-contact laser scanning

Sizes Available (mm)

| 30.20.20 | 30.25.15 | 30.25.20 |

| 40.20.20 | 40.25.15 | 40.25.20 |

| 50.20.20 | 50.25.15 | 50.25.20 |

| 60.20.20 | 60.25.15 | 60.25.20 |

Accuracy

| Volumetric Accuracy | From 3 µm + L/350 |

| Repeatability | From 3 µm |

| Velocity | From 611 mm/s |

| Acceleration | From 500 mm/s2 |

Probing Options

Multi-sensor

|

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

ALTERA ACCESSORIES

gantry

LK Metrology’s gantry solutions are designed to measure larger parts that wouldn’t be practical to measure using other types of CMMs. This type of CMM presents practical advantages: low maintenance costs, a contaminant-optimized design, and the ability for operators to walk into the inspection area to physically check the assembly during operation.

AEROS

The ideal measurement solution for large precision components

The AEROS Series are an innovative mechanical design that ensures durable metrology, measurement data stability and low maintenance and calibration costs. The AEROS features aluminum alloy Z-axis spindles and a “Single Read” scale system on the X-axis.

The AEROS S models offer medium to large Gantry-style metrology for improved structural stability and adaptability.

The AEROS P gantry systems are also designed to inspect large, geometrically accurate components, such as marine engines, transmissions, large transportation vehicles, large parts and tools with free-form and sculptured surfaces. The AEROS P CMMs work particularly well in aerospace, strategic and energy settings. The CMM’s structure, “Dual Drive” motion and “Dual Read” positioning system on the X-axis beams limit structural deformations during movement, ensuring excellent metrological performance.

- Ideal for large precision components

- Uses the latest innovations in aluminum and steel CMM guideway technology

- Open design is extremely adaptable, providing full access to the work area

Sizes Available (mm)

AEROS30.20.10 up to 60.25.18 |

AEROS S40.20.20 up to 60.30.20 |

AEROS P50.25.20 up to 60.35.25 |

Accuracy

| Volumetric Accuracy | From 4.3 µm + 4L/1000 (AEROS) | From 4.3 µm + 5L/1000 (AEROS S) | From 7.0 µm + 8L/1000 (AEROS P) |

| Velocity | From 500 mm/s (AEROS) | From 530 mm/sec (AEROS S) | From 530 mm/sec (AEROS P) |

| Acceleration | From 1200 mm/s2 (AEROS) | From 800 mm/s2 (AEROS S) | From 800 mm/s2 (AEROS P) |

Laser Scanning

|

|

|

|

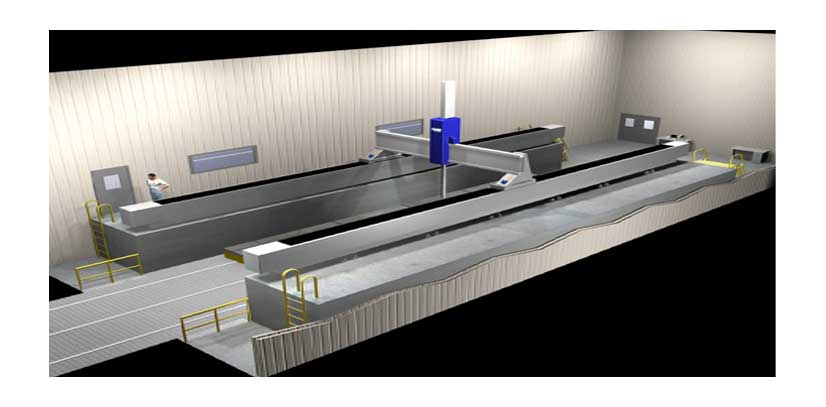

ULTRA

Ultra: Very-large-scale measurement for very-large-scale precision engineering

The Ultra range of solutions has a proven pedigree within aerospace airframe and large blades inspection, land transportation, large engine and transmission components, large scale gears, power generation, large turbines, maritime engine and propellers, and locomotive components.

Made for very-large-scale measurement applications the LK Metrology Ultra CMM Series, with its elevated guideway design, offers among the most flexible solutions in the industry today for 3D dimensional inspection.

The Ultra range offers three machine design variants, the monolithic design with an integrated work-table, the classic gantry design, and the proven guideways on U-foundation design which can be implemented as above ground, ground level, or, in sub-ground foundation pit installations. All variants are based upon a common modular design concept providing high performance, reliability and an easy to maintain measuring system.

Laser Scanning

|

|

|

|

horizontal

Horizontal CMMs are designed for elongated parts and assemblies. LK Metrology produces a durable range of horizontal CMMs for every budget and accuracy requirement.

HC-90

Bridge CMM accuracy with Horizontal flexibility

Geometric stability at high speed, and resistance to harsh environments are difficult to achieve using aluminum or cast-iron guideways with mechanical bearings. The HC-90’s ceramic column and runs on LK Metrology’s proprietary air suspension system to deliver Bridge-like accuracy for larger components.

- High-quality 96% Alumina Ceramic for optimal speed, stiffness and long-lasting measurement accuracy

- Designed for production-line integration

- Flexible positioning and articulation

- Four design options

HC-90TTable-mounted single arm guideway

|

HC-90RSingle arm guideway

|

HC-90TRTwin arm guideway

|

HC-90WTRFloor-integrated twin guideway

|

Probing Options

Tactile Probes

Multi-sensor

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

HD-90

Aluminum Horizontal CMM

An advanced design for cost-effective dimensional inspection of large components typical of the automotive, land transport and heavy industries.

- Single or double arm configurations Designed for production-line integration

- Air bearings on the YZ axes,

- Double recirculating bearing guideways on the X-axis

- Optional cast iron work-plates and loading/unloading systems

- Protective covers to ensure thermal and contaminant insulation

- Simplified manual or automated part loading and unloading

Probing Options

Multi-sensor

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

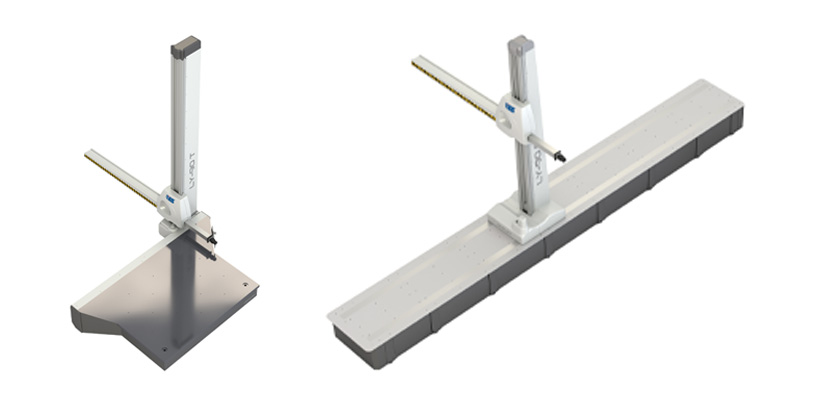

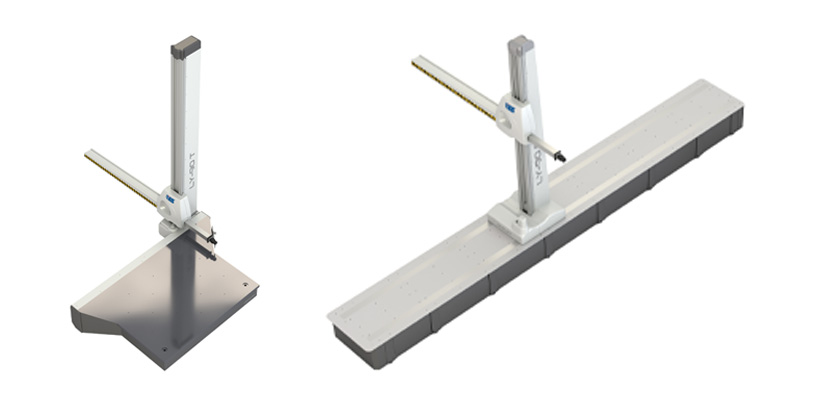

LY-90

LY-90R – Runway-based horizontal CMM

The LY-90R is a runway-based CMM designed for part accessibility. Developed specifically for automotive, land transport and heavy industry quality inspection applications, the LY-90R can be installed on a pneumatic vibration isolation system for use in production environments, without the need for dedicated foundations for the system

- Runway horizontal arm CMM

- Measurement system with linear optical transducers

- Control of movement through servo motors

- Air bearings on the Y-Z axes, precision guideways on the X-axis

- Mechanical carrier counterbalance with safety brake

- Optional cast iron work-plates

LY-90T – Table-mounted horizontal CMM

The LY-90T is a table CMM designed for part accessibility. Developed specifically for car-body and sub-assembly quality inspection applications, the LY-90T is the perfect solution for sheet-metal and plastic component metrology.

- Console-mounted horizontal arm

- Measurement system with linear optical transducers

- Control of movement through servo motors

- Air bearings on the Y-Z axes and precision guideways on the X-axis

- Mechanical carrier counterbalance with safety brake

- Optional cast iron work-plates

Probing Options

Multi-sensor

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

SOFTWARE

LK Metrology offers a range of multi-sensor CMM software packages to control and gather measurement data.

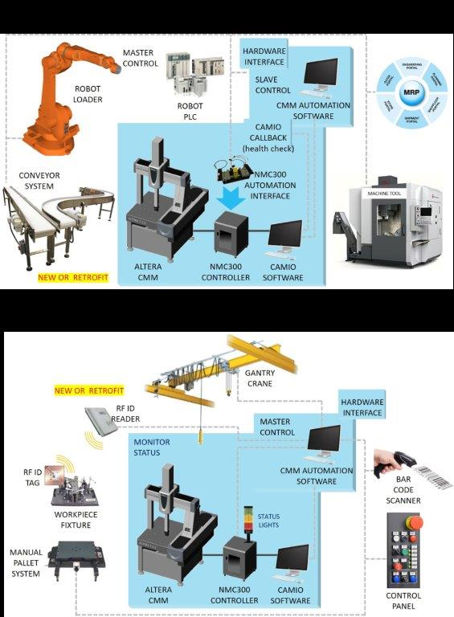

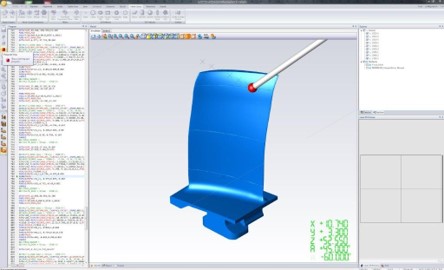

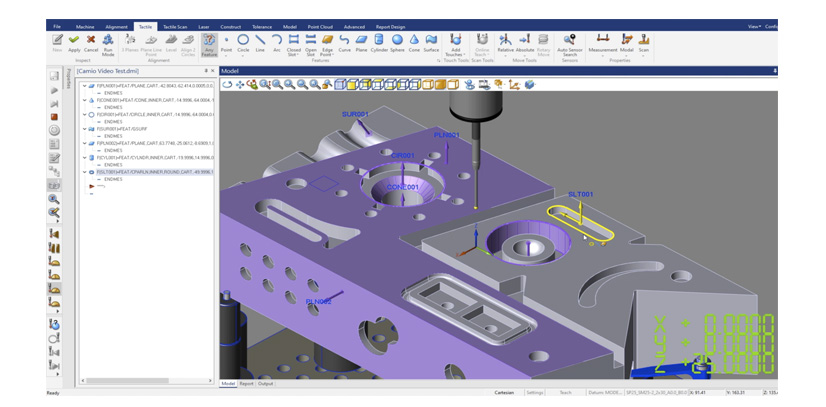

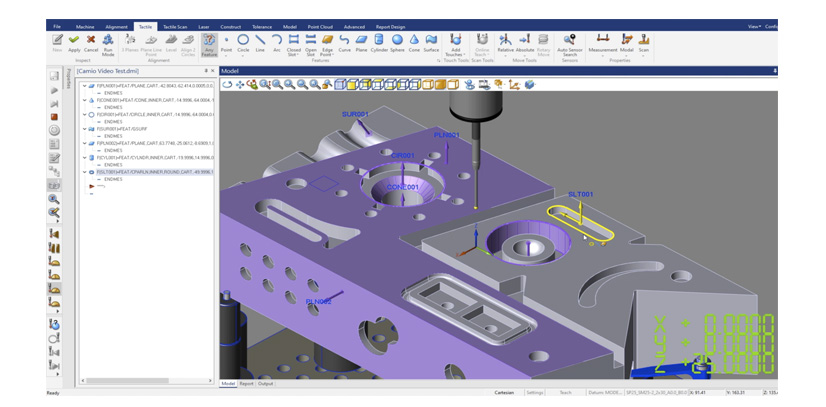

CAMIO 2022

Metrology Software for Industry 4.0

CAMIO is a highly customizable software package that allows manufacturers to harness the full pothential of their in-line CMMs without spending a fortune on software development. Designed from the ground up to easily control, gather data, and automate almost any CMM, CAMIO comes with a full Industry 4.0 toolset to increase your metrology quality, accuracy, and throughput and allows you to build interoperable inspection workflows, reports, virtual assemblies, and much much more.

- Automated inspection software

- Fully programmable

- Built for engineers and operators

Optional software modules

CAMIO Gear – to measure helical gears, spur gears, partial gears, inner and outer gears…

CAMIO Blade – point cloud blade inspection software module for airfoils and blades (aerospace and energy)

CAMIO SPC – to automate statistical process control

CAMIO Point Cloud – for point cloud inspection

ARCOCAD

Full-featured dimensional metrology software

ARCOCAD is a full-featured dimensional metrology application that controls, gathers data, and automates CMM processes. Built to optimize accuracy, measurement speed, and programability, ARCOCAD drives CMM hardware and gathers measurement data producing detailed inspection reports and graphical representations.

- Designed for Industry 4.0 metrology

- Fully programmable

- Integrated with Metrology Gate

Optional software modules

ARCO Gear – to measure helical gears, spur gears, partial gears, inner and outer gears…

ARCO Blade – point cloud blade inspection software module for airfoils and blades (aerospace and energy)

ARCO SPC – to automate statistical process control

ARCO Point Cloud – for point cloud inspection

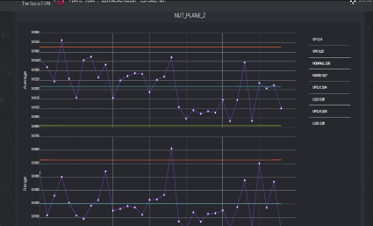

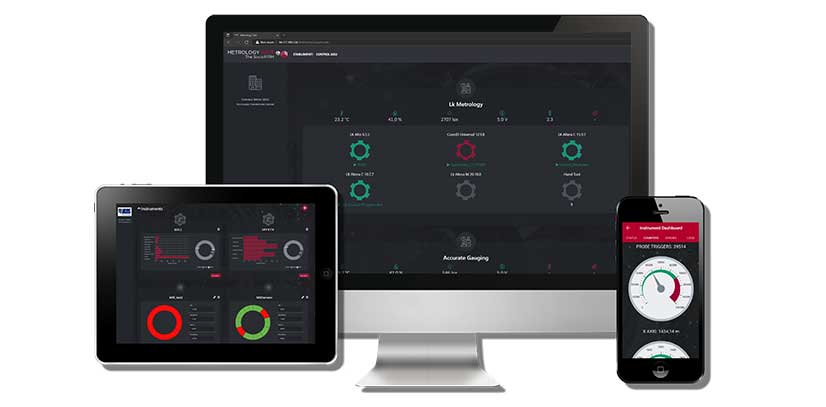

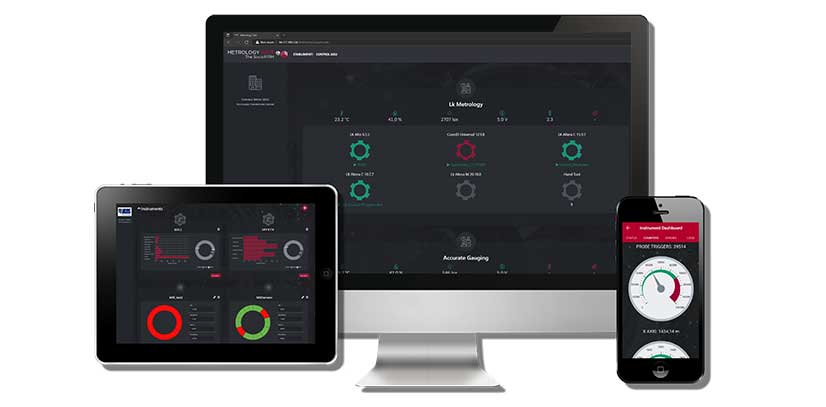

Metrology Gate

Machine Monitor

Keep track of your machines from your mobile app or your web browser.

Have the full status under control: the program running, environmental information and the history of the hardware errors.

A single dashboard will always keep you updated.

Statistical Evaluation

All the measuring results stored in a single repository accessible anytime and everywhere.

A full statistical evaluation of the data lets any user understand how the production is going without going through desktop application, justdownload the app to always be connected

Comparative Analysis

Get an analytic analysis of the measuring results comparing the different machines and measuring tools production in order to get a view

of the performance.

This is a fundamental help to plan your next maintenance or a help in choosing the next machine tool.

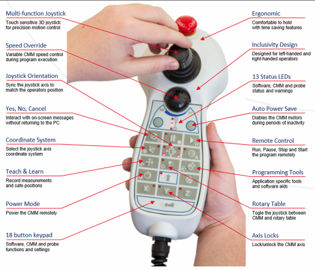

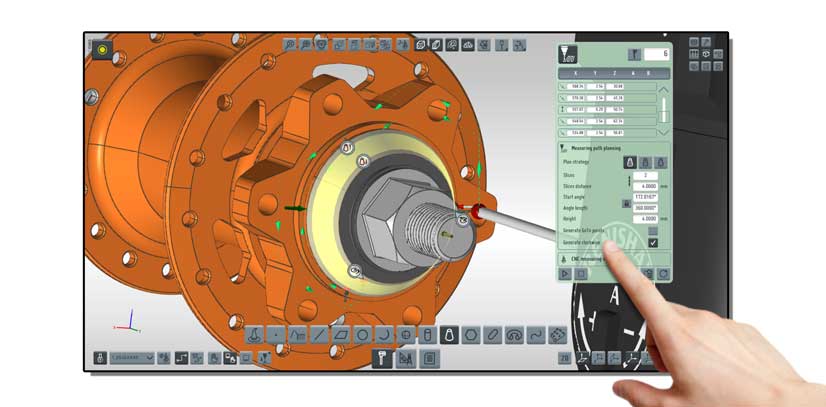

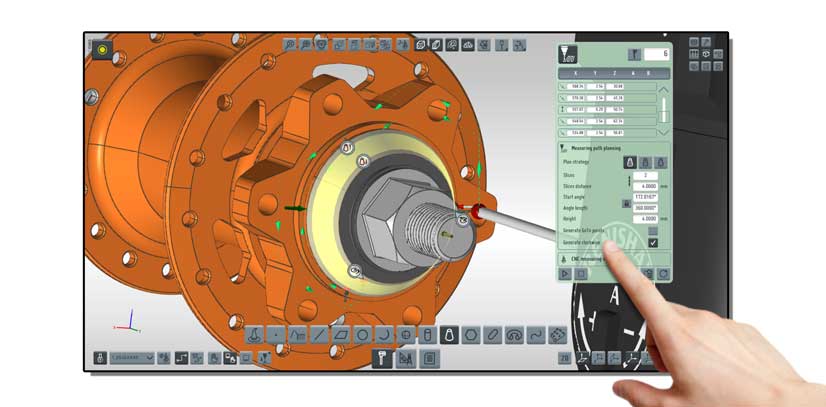

TouchDMIS

Metrology Power with Simplicity

TouchDMIS combines the power required for advanced users with the simplicity needed for new users, making measurement capability easily accessible from the CAD room to the production floor.

TouchDMIS, in its 3rd iteration of CMM software, has taken on the mission of creating a user interface that intuitively leads the user through the basic measurement process.

Software that Simplifies Your CMM

The intuitive interface of TouchDMIS has been ergonomically designed to provide maximum productivity for both novice and expert CMM users.

TouchDMIS has no drop-down menus or stacked toolbars with all functionality accessed with just a touch of your finger.

Maximize Your Productivity

TouchDMIS requires just a few hours of training and offers an incredibly short learning curve.

The software can be operated entirely via touchscreen, using intuitive touch, swipe, and gesture commands.

Create Reports

TouchDMIS offers a choice of inspection reports for Real-time reporting.

XML, Excel, TXT, and PDF exportable output provides flexible reporting.

Applications Typical for TouchDMIS

TouchDMIS metrology software is often used in the following applications

- Inspection

- Reverse Engineering

- Part Archiving

- Rapid Prototyping

- Engineering Analysis

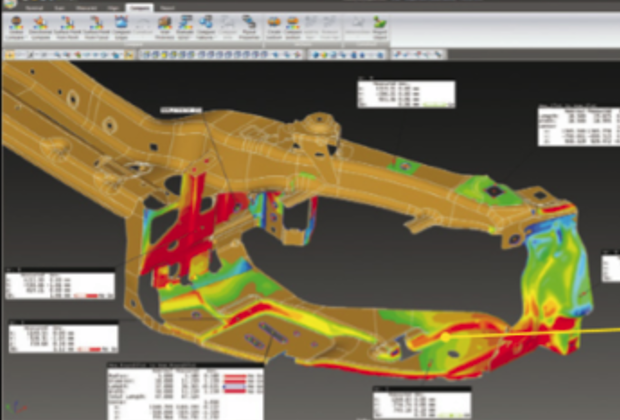

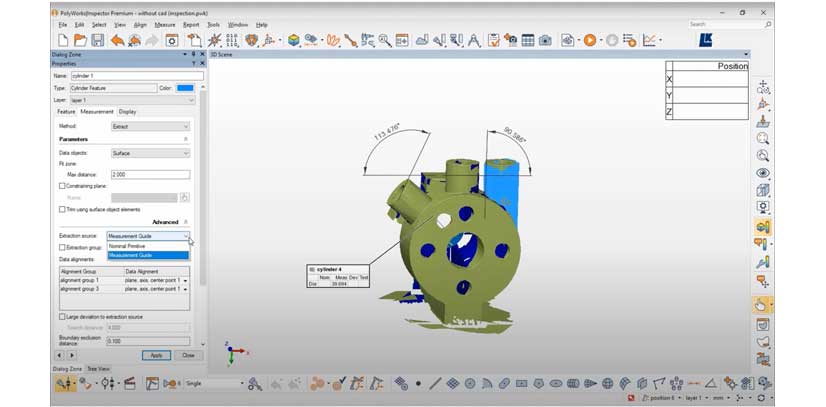

Polyworks

PolyWorks|Inspector™ is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

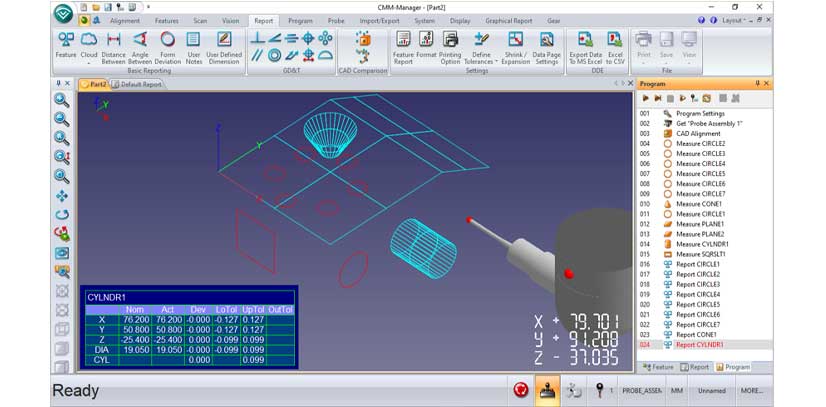

CMM Manager

CMM-Manager by QxSoft is a task-oriented, highly intuitive, 3D CAD based, software package for any CMM. Software is available for both new and existing CMM hardware. We offer software for vision, manual, portable, and CNC coordinate measuring machines. Avoid costly hardware retrofits, our software connects directly to your existing CMM or Metrology equipment by plug-n-play retrofit.

MODULES

SENSORS

Our multi-sensor CMMs can be equipped with an extensive range of scanning and trigger contact sensors and optical scanning sensors, tool changing automation hardware and probe heads.

LASER SCANNERS

VIVID SLK20

High accuracy, high resolution blue laser CMM scanner

Thanks to VIVID laser scanner technology from LK Metrology, the SLK20 provides quality professionals with an opportunity to maximize efficiency when measuring complex surfaces, small details, fragile parts, dark materials and reflective surfaces – by overcoming the limitations of tactile inspection and other non-contact technologies.

VIVID Technology

VIVID multiple exposure technology quadruples the dynamic range of the laser scanner. More surfaces, including the most challenging dark, transparent or highly reflective materials can be measured in a single pass or the laser scanner. Phasing the exposure time during scanning to match the part surface, optimizes acquisition speeds and data quality. Exposure settings are included for typical applications, with fully configurable user settings for individual requirements.

| Scanner Type | Line |

| Laser line width | 24 mm (.95 in) |

| Points/second | 268k |

| Resolution (near, mid, far) | 9.3, 10.9, 12.9 µm |

| Scan Rate | 140 Hz |

NIKON L100

The newest laser scanner introduces the 4th generation Enhanced Sensor Performance (ESP4). With a high point resolution along a 100 mm wide stripe, the L100 achieves a data collection rate of 200,000 points per second. As the most productive line scanner, it offers double the point resolution, 2.5 x the scanning speed and 30% better accuracy than other scanners. With a projected field-of-view, the L100 makes for easy path planning and the ESP4 means it is the most adept at handling difficult shiny or reflective surfaces. Like other line scanners, the L100 is often used for surface and feature inspection in automotive and aerospace applications. However, its specification makes it the fastest and most accurate multi-purpose scanner, therefor the most proficient tool for almost any application.

| Scanner Type | Line |

| Laser line width | 100 mm (3.9 in) |

| Points/second | 200k |

| Resolution | 42 µm |

| Standoff | 135 |

NIKON LC15Dx

The high accuracy laser scanner LC15Dx features a small laser line, and a higher number of points along said line for a higher resolution, to make it the most accurate laser scanner available on the market today. The LC15Dx perfectly suits digitizing compact or detailed objects with higher point density and tighter tolerances, both suited for surfaces and features. Considering this, the LC15Dx is often used for the inspection of high precision parts. The LC15Dx closes the gap between laser scanner and tactile probe accuracy, making it a viable alternative to a tactile probe for an increasing number of high precision CMM applications. In tests, the LC15Dx achieved the accuracy associated with using a tactile probe on a CMM. The probing error of 1.9 µm mirrors the accuracy expected when using a CMM fitted with a tactile probe. Unlike a tactile probe though, the LC15Dx uses non-contact 3D laser triangulation to measure the surface directly and eliminate probe compensation errors.

| Scanner Type | Line |

| Laser line width | 15 mm (0.6 in) |

| Points/second | 70k |

| Resolution | 22 µm |

| Standoff | 68 |

NIKON XC65Dx

The XC65Dx Cross Scanner utilizes three laser stripe scanners in one sensor. The three lasers are spaced 120 degrees apart and observe the part in question from three angles. By doing this, the XC65Dx can acquire the same amount of data with just one scan than a line scanner would do in three scans. This feature makes the XC65Dx well suited to feature inspection of slots, holes and grooves in sheet metals or items with a large complex surface area. It is often used in automotive BIW (Body-in-White) inspection, gap & flush and driveline casting inspection. Whilst the long standoff Cross Scanner retains the many advantages of the original XC65Dx, it also excels in dealing with accessing difficult-to-reach or obscured areas. By capturing geometries up to a distance of 170 mm (7.1”), the scanner gains optimum access to cavity surfaces of body-in-white structures or can scan over the clamps that hold components in position. For these reasons, the XC65Dx-LS scanner is used a lot on horizontal-arm CMM in the automotive industry.

| Scanner Type | Cross |

| Laser line width | 3x 65 mm (2.6 in) |

| Points/second | 75k |

| Resolution | 65 µm |

| Standoff | 107/202 |

MANUAL SYSTEMS

A range of fixed and manually adjustable heads that connect a touch-trigger probe to the machine quill, allowing flexible inspection of complex components.

Manual Indexing

MH20i – Indexable head for use with TP20 stylus modules

Manual indexable probe head that combines the TP20 kinematic stylus module mount with two axis indexing, enabling flexible stylus changing and repeatable probe re-orientation.

| Head Type | Manual Indexing |

| Head Positions | 168 |

| Angular Tilt | 0o to +90o in 15o steps |

| Angular Rotation | ±180o in 15o steps |

| Touch Probe | Integral |

PH6 – Fixed head with one probe socket

The PH6 is a small diameter, vertical probe head with one M8 thread probe mount for a single probe, with an integral cable.

- Compatible with M8 probes

- Shank mounted

- Simple to install

| Head Type | Fixed (Vertical) |

| Head Positions | – |

| Angular Tilt | – |

| Angular Rotation | – |

| Touch Probe | TP20, TP200 |

PH6M – Fixed head with autojoint

The PH6M is compatible with multi-wired probes TP7M, OTP6M and SP600M, as well as the complete Renishaw probe range through the use of the PA series of adaptors.

| Head Type | Fixed (Vertical) |

| Head Positions | – |

| Angular Tilt | – |

| Angular Rotation | – |

| Touch Probe | TP20, TP200, SP25M |

CMM 3-AXIS SYSTEMS

Renishaw probe systems are available in a wide variety of types to

enable a best match for a particular application

Motorized Head Systems

Motorized heads enable automated, repeatable re-orientation of probes to allow access to features on all faces of the part, improving the capability of the CMM and maximizing productivity.

PH10T PLUS

The PH10T PLUS is similar to the PH10M PLUS, except that it features an M8 thread probe mount in place of the autojoint. All M8 threaded probes, such as TP20 and TP200, and extension bars fit directly onto the head. The PH10T PLUS is fully compatible with all of Renishaw’s stylus and module change systems.

| Head Type | Motorized Indexing |

| Head Positions | 720 |

| Angular Tilt | 0o to +105o in 7.5o steps |

| Angular Rotation | 0o to ±180o in 7.5o steps |

| Touch Probe | TP20, TP200 |

PH10M PLUS

The PH10M PLUS can carry long extension bars and complex probes such as SP25M or TP7M. The highly repeatable autojoint allows rapid probe or extension bar changing without the need for re-qualification.

| Head Type | Motorized Indexing |

| Head Positions | 720 |

| Angular Tilt | 0o to +105o in 7.5o steps |

| Angular Rotation | 0o to ±180o in 7.5o steps |

| Touch Probe | TP20, TP200, SP25M |

| Laser Scanner | LC15Dx, LC60Dx, L100, C65Dx/LS, VIVID SLK20 |

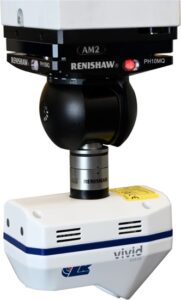

PH10MQ PLUS

The PH10MQ PLUS is a variant of the PH10M PLUS that allows the motorised head to be attached directly to the quill with the B-axis of the head inside the quill itself.

| Head Type | Indexing Head |

| Head Positions | 720 |

| Angular Tilt | 0o to +105o in 7.5o steps |

| Angular Rotation | 0o to ±180o in 7.5o steps |

| Touch Probe | TP20, TP200, SP25M |

| Laser Scanner | LC15Dx, LC60Dx, L100, C65Dx/LS, VIVID SLK20 |

PHS-2

Servo Head – PHS-2 is designed to meet the arduous requirements of ‘body-in-white’ measurement, where fine angular position and long reach are needed.

| Head Type | 5-Axis Wrist |

| Head Positions | Infinite |

| Angular Tilt | -184o to 184o in 1µm steps at 100mm radius |

| Angular Rotation | -184o to 184o in 1µm steps at 100mm radius |

| Touch Probe | TP20, TP200, SP25M |

| Laser Scanner | LC15Dx, LC60Dx, L100, C65Dx/LS, VIVID SLK20 |

Touch-Trigger Probe Systems

Touch-trigger probes measure discrete points, making them ideal for inspection of 3-dimensional geometric parts.

TP20

Compact module changing touch-trigger probe, which allows the use of a range of stylus configurations and extensions to access features on complex parts.

| Probe Type | Touch Trigger |

| Min. stylus diameter | 0.3 (0.012) |

| Max. stylus diameter | 60 (2.4) |

| Max. probe extension | 300 (11.8) |

| Min. probing force | 0.055 N |

TP200

A compact, module-changing probe that uses strain-gauge mechanisms for higher accuracy and longer life than kinematic touch-trigger probes.

| Probe Type | Touch Trigger |

| Min. stylus diameter | 0.3 (0.012) |

| Max. stylus diameter | 100 (3.9) |

| Max. probe extension | 300 (11.8) |

| Min. probing force | 0.02 N |

Scanning Probe Systems

Scanning probes can acquire several hundred surface points each second, enabling measurement of form as well as size and position.

SP25M

At only 25 mm in diameter, and with a range of scanning and touch-trigger modules, the SP25M is the world’s most compact and versatile scanning probe system.

| Probe Type | Scanning |

| Min. stylus diameter | 0.5 (0.02) |

| Max. stylus diameter | 400 (15.7) |

| Max. probe extension | 100 (3.9) |

| Min. probing force | 0.1 N |

SP80

Combining long stylus reach with ultra-high accuracy performance, SP80 is the first-choice scanning probe for many applications.

| Probe Type | Scanning |

| Min. stylus diameter | 0.3 (0.012) |

| Max. stylus diameter | 1000 (39.4) |

| Max. probe extension | – |

| Min. probing force | 2.2 N |

CMM 5-AXIS SYSTEMS

Unlike conventional CMM measurement methods, Renishaw’s 5-axis technology uses the synchronized motion of the CMM and the head axes to

minimize the machine’s dynamic errors at ultra‑high measuring speeds.

REVO

5-Axis Measurement System

A REVO® system delivers high performance scanning, non-contact inspection and surface finish analysis on a single CMM

High-speed measurement

- Up to 500 mm/sec resulting in increased part throughput

- Data collection rates up to 4,000 points per second

- Infinite positioning and 5-axis motion reduces non-productive transitions between features

- Rapid calibration with all positions inferred means more time measuring

High system accuracy

- 5-axis scanning minimises CMM motion and the associated dynamic errors

- Stylus wear minimised by extremely low scanning forces

- Infinite positioning and five-axis motion aid access to difficult features

- Tip-sensing further adds to the systems’ accuracy and flexibility

Great flexibility

- Maximum reach up to 800 mm from centre of head rotation

- Multi-sensor probe and stylus changing capability

- Renishaw UCCserver software application (based on I++ DME command protocol) provides the interface for REVO-2 control

- The removable probe system, used in conjunction with a low cost changer, provides added system flexibility

RSP2 -RSP2 is a dedicated lightweight tip-sensing probe for use on REVO systems, capable of 2D-scanning (x, y) and 3D-touch trigger measurement.

RSP3 – The RSP3 range complements the RSP2 probe, providing the REVO system with 3D-scanning (x,y,z) and crank stylus capabilities. It is used for

3-axis scanning, such as with a fixed REVO head angle during measurement.

| Head Type | Fixed Head |

| Head Positions | Infinite |

| Angular Tilt | -100o to +120o |

| Angular Rotation | Continuous |

| Touch Probe | RSP2, RSP3 |

PH20

Unlike conventional touch-trigger measurement methods which rely on speeding up the motion of the CMM’s 3 axes to measure quickly, PH20 utilizes the head motion technology developed for

the multi-award winning REVO system to minimize the dynamic errors of the CMM at higher measurement speeds.

PH20’s unique ‘head touches’ allow measurement points to be taken by moving only the head, rather than the CMM structure. Points can be taken faster, and with improved accuracy and repeatability.

Furthermore, 5-axis motion eliminates time spent indexing the head. Together these speed increases typically result in a 3-fold improvement in throughput over conventional systems.

| Head Type | 5-Axis Continuous |

| Head Positions | Infinite |

| Angular Tilt | ±115o |

| Angular Rotation | Infinite |

| Touch Probe | Integral |

Accessory Name

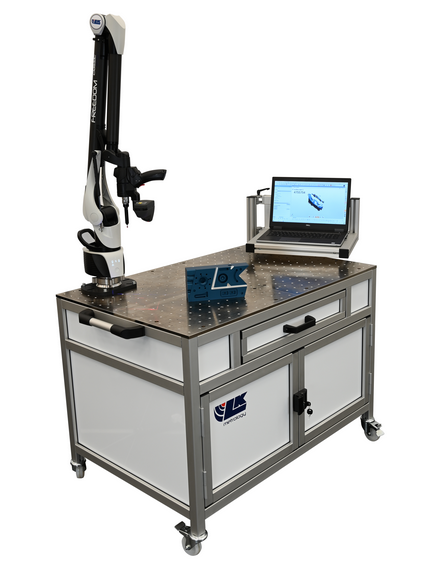

PORTABLE MEASURING ARMS

Take your CMM with you to any location with our portable measurement solutions. Our portable solutions allow you to perform rapid, battery-operated measurements where the operator can move freely around the part being measured.

FREEDOM ARM

Portable productivity, practicality, and flexibility

Equipped with Wi-Fi connectivity, complete battery operation, and a mobile workstation, the FREEDOM ARM gives you total mobility for your metrology needs.

With 6 axis and 7 axis portable measuring arms – for quality control, on-machine verification, reverse engineering or 3D modelling, the FREEDOM ARM series features three accuracy levels and several sizes in different portable arm configurations. These can be enhanced with manual-moving rotary tables, touch probes, and laser scanner options.

Designed for productivity, practicality, and flexibility, LK Metrology’s FREEDOM ARM performs challenging metrology tasks in almost any manufacturing environment.

- Go-to Measurement Where It Benefits You Most …

- Touch Probe

- 6-axis

- Laser Scanner & Touch Probe

- 7-axis

Accessory Name

BRIDGE CMM

The Bridge product family’s bridge and quill design provide a thermally stable and ultra-stiff structure for long lasting accuracy and structural stability. This makes our multi-sensor ready, pneumatically-raised CMMs some of the most accurate and durable CMMs on the market.

Ultra-Compact Aluminium CMM

Optimised for the new challenges of dimensional quality control, where parts are becoming smaller, designs more complex and design limits are narrowing, the ALTO is ideal for quality professionals taking their first steps in building up an automated inspection capability, with easy-to-use software and versatile options.

ALTO is a compact CMM with space-saving features such as the half-gantry design, fully integrated electronics and retracting monitor arm, making ALTO the perfect fit where space is limited.

Supplied with automated stylus changing as standard, ALTO is available with a standard motorised indexing probe head, or the latest high-performance 5-axis probe system for maximum efficiency. With access from 3 sides for part loading, ALTO is ideal for production areas or quality control rooms.

Additionally ALTO employs high-tech aluminium alloy for the structure and guideways of its moving half-gantry. This cost-effective materials technology provides the stiffness needed for accuracy, while keeping ALTO’s moving mass to a minimum for high-speed measurement.

- Aluminium half-gantry design with micro-machined guideways for precision and hard anodization for resistance to wear and corrosion

- Air bearings with large bearing spread for dynamic stability and a low maintenance, self-cleaning design

- Smooth, exact motion control friction drives enabling zero hysteresis, low maintenance

- 0.1µm encoders – high resolution optical scale system for accuracy

- Optional manufacturing environment-friendly anti-vibration features

- Temperature compensation for quality labs and workshop environments

- Integrated screen and keyboard arm and optional controller mounting

Sizes Available (mm)

| 6.5.5 |

Accuracy

| Volumetric Accuracy | From 2.5+3.0L/1000 |

| Repeatability | From 2.3 µm |

| Velocity | From 500 mm/sec |

| Acceleration | From 1500 mm/sec2 |

Probing Options

Tactile Probes

|

|

Multi-sensor

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

Compact CMM – Perfect

for smaller spaces

The ALTERA C range of space-efficient ceramic-bridge CMM uses the latest metrology software, multi-sensor technology and design, offering high accuracy measurement and efficient throughput for measurement tasks in quality laboratories and shopfloor environments.

- Compact footprint

- High accuracy measurement and efficient throughput

- Integrated technology with optional monitor & keyboard

Sizes Available (mm)

| 7.7.5 | 10.7.7 | 12.9.7 |

| 10.7.5 | 15.9.7 |

Accuracy

| Volumetric Accuracy | From 1.7 µm + L/333 |

| Repeatability | From 1.5 µm |

| Velocity | From 722 mm/s |

| Acceleration | From 1,903 mm/s2 |

Probing Options

Tactile Probes

|

|

|

|

Multi-sensor

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

Premium multipurpose CMM with the most advanced capabilities in its class

The ALTERA S’s advanced multi-sensor ready technology optimizes CMM throughput and provides the opportunity to broaden the application scope to new materials and components as needs change, without additional wiring or controllers.

The ALTERA S’s ceramic design, stiffness-to-weight ratio and temperature resistance ensures a high-precision and durability.

- Cutting-edge design built for flexibility

- Advanced multi-sensor ready technology

- Innovative folding guideway panel design

Sizes Available (mm)

| 7.5.5 | 8.7.6 | 10.10.8 |

| 10.7.6 | 12.10.8 | |

| 15.7.6 | 15.10.8 | |

| 20.10.8 |

Accuracy

| Volumetric Accuracy | From 1.8 µm + L/400 |

| Repeatability | From 1.7 µm |

| Velocity | From 762 mm/s |

| Acceleration | From 2,306 mm/s2 |

Probing Options

Tactile Probes

|

|

Multi-sensor

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

High-speed tactile probe & laser scanning Mid-Size Bridge CMM

Very high accuracy multipurpose, multi-sensor ready CMM with optimized throughput. Like many of the CMMs in the ALTERA family, the ALTERA M is flexible in terms of application scope, materials and components allowing the CMM to adapt easily to changing needs.

The ALTERA M’s size, ceramic design, stiffness-to-weight ratio and temperature resistance ensure rapid, high-precision and durable metrology tasks as required by medical equipment, automotive and aerospace manufacturers.

- Designed for high-speed tactile probe & laser scanning applications

- Wide range of sizes available

- Preferred choice for automotive & aerospace OEMs

Sizes Available (mm)

| 7.5.5 | 8.7.6 | 10.10.8 |

| 10.7.6 | 12.10.8 | |

| 15.7.6 | 15.10.8 | |

| 20.10.8 |

Accuracy

| Volumetric Accuracy | From 1.8 µm + L/400 |

| Repeatability | From 1.7 µm |

| Velocity | From 762 mm/s |

| Acceleration | From 2,306 mm/s2 |

Probing Options

Tactile Probes

|

Multi-sensor

|

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

5-axis multi-sensor CMM for Speed & Flexibility

Powered by REVO, MODUS and dedicated sensors for contact, non-contact and surface finish scanning, the ALTERA SCANtek5 system offers very high throughput as required in automotive and aerospace component manufacturing.

The ALTERA SCANtek5 CMMs feature very high accuracy 5-axis multi-sensors ensuring flexible head positioning and rapid scanning.

- Revolutionary 5-Axis multi-sensor technology

- Ultra fast scanning

- Infinite head positioning

- Surface finish analysis

Sizes Available (mm)

ALTERA M & ALTERA SL sizes available upon request

Accuracy

| Volumetric Accuracy | From 1.5 µm + L/375 (ALTERA M) | From 1.5 µm + L/400 (ALTERA SL) |

| Repeatability | From 1.5 µm (ALTERA M) | From 0.7 µm (ALTERA SL) |

| Velocity | From 833 mm/s (ALTERA M) | From 318 mm/s (ALTERA SL) |

| Acceleration | From 1,676 mm/s2 (ALTERA M) | From 566 mm/s2 (ALTERA SL) |

Probing Options

Multi-sensor

|

Laser Scanning

|

|

|

|

Sub-micron accuracy, speed and market-leading flexibility

LK Metrology’s most advanced high-accuracy CMM, the ALTERA SL features multi-sensor ready technology, ultrafast dynamics/raised shoulders, optional sub-micron precision, increased stiffness, stability, and rapid throughput.

- SL series is the most advanced high accuracy CMM LK offers

- Innovative short-leg bridge design

- High Accuracy version achieves sub-micron accuracy

Sizes Available (mm)

ALTERA SL

| 8.7.6 | 10.10.8 | 15.12.10 | 25.15.10 | 20.15.15 | 25.20.15 |

| 10.7.6 | 15.10.8 | 20.12.10 | 25.15.15 | ||

| 15.7.6 | 20.10.8 | 25.12.10 | |||

| 25.10.8 |

ALTERA SLHA

| 8.7.6 | 10.10.8 | 15.12.10 |

| 10.7.6 | 15.10.8 | 20.12.10 |

| 15.7.6 | 20.10.8 | 25.12.10 |

| 25.10.8 |

Accuracy

| Volumetric Accuracy | From 1.1 µm + L/400 (ALTERA SL) | From 0.7 µm + L/600 (ALTERA SLHA) |

| Repeatability | From 0.7 µm (ALTERA SL) | From 0.5 µm (ALTERA SLHA) |

| Velocity | From 850 mm/s (ALTERA SL) | From 317 mm/s (ALTERA SLHA) |

| Acceleration | From 1,407 mm/s2 (ALTERA SL) | From 566 mm/s2 (ALTERA SLHA) |

Probing Options

Multi-sensor

|

|

Scanning

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

Proven pedigree with large-scale applications

The Maxima range of solutions has a proven pedigree within aerospace, large-scale commercial vehicle applications and manufacturers of large performance critical components.

The unique LK Metrology, proprietary design, low gap high efficiency air bearings and zero hysteresis drive systems ensure premium quality, high accuracy and throughput of Maxima CMMs to meet the needs of large-scale manufacturers.

- Very large-scale metrology applications

- Bonded ceramic materials

- High performing beam and spindle construction

- Greater resistance to time, wear and temperature variations

- Touch-trigger, contact and non-contact laser scanning

Sizes Available (mm)

| 30.20.20 | 30.25.15 | 30.25.20 |

| 40.20.20 | 40.25.15 | 40.25.20 |

| 50.20.20 | 50.25.15 | 50.25.20 |

| 60.20.20 | 60.25.15 | 60.25.20 |

Accuracy

| Volumetric Accuracy | From 3 µm + L/350 |

| Repeatability | From 3 µm |

| Velocity | From 611 mm/s |

| Acceleration | From 500 mm/s2 |

Probing Options

Multi-sensor

|

|

Scanning

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

ALTERA ACCESSORIES

gantry

LK Metrology’s gantry solutions are designed to measure larger parts that wouldn’t be practical to measure using other types of CMMs. This type of CMM presents practical advantages: low maintenance costs, a contaminant-optimized design, and the ability for operators to walk into the inspection area to physically check the assembly during operation.

The ideal measurement solution for large precision components

The AEROS Series are an innovative mechanical design that ensures durable metrology, measurement data stability and low maintenance and calibration costs. The AEROS features aluminum alloy Z-axis spindles and a “Single Read” scale system on the X-axis.

The AEROS S models offer medium to large Gantry-style metrology for improved structural stability and adaptability.

The AEROS P gantry systems are also designed to inspect large, geometrically accurate components, such as marine engines, transmissions, large transportation vehicles, large parts and tools with free-form and sculptured surfaces. The AEROS P CMMs work particularly well in aerospace, strategic and energy settings. The CMM’s structure, “Dual Drive” motion and “Dual Read” positioning system on the X-axis beams limit structural deformations during movement, ensuring excellent metrological performance.

- Ideal for large precision components

- Uses the latest innovations in aluminum and steel CMM guideway technology

- Open design is extremely adaptable, providing full access to the work area

Sizes Available (mm)

AEROS30.20.10 up to 60.25.18 |

AEROS S40.20.20 up to 60.30.20 |

AEROS P50.25.20 up to 60.35.25 |

Accuracy

| Volumetric Accuracy | From 4.3 µm + 4L/1000 (AEROS) | From 4.3 µm + 5L/1000 (AEROS S) | From 7.0 µm + 8L/1000 (AEROS P) |

| Velocity | From 500 mm/s (AEROS) | From 530 mm/sec (AEROS S) | From 530 mm/sec (AEROS P) |

| Acceleration | From 1200 mm/s2 (AEROS) | From 800 mm/s2 (AEROS S) | From 800 mm/s2 (AEROS P) |

Laser Scanning

|

|

|

|

Ultra: Very-large-scale measurement for very-large-scale precision engineering

The Ultra range of solutions has a proven pedigree within aerospace airframe and large blades inspection, land transportation, large engine and transmission components, large scale gears, power generation, large turbines, maritime engine and propellers, and locomotive components.

Made for very-large-scale measurement applications the LK Metrology Ultra CMM Series, with its elevated guideway design, offers among the most flexible solutions in the industry today for 3D dimensional inspection.

The Ultra range offers three machine design variants, the monolithic design with an integrated work-table, the classic gantry design, and the proven guideways on U-foundation design which can be implemented as above ground, ground level, or, in sub-ground foundation pit installations. All variants are based upon a common modular design concept providing high performance, reliability and an easy to maintain measuring system.

Laser Scanning

|

|

|

|

horizontal

Horizontal CMMs are designed for elongated parts and assemblies. LK Metrology produces a durable range of horizontal CMMs for every budget and accuracy requirement.

Bridge CMM accuracy with Horizontal flexibility

Geometric stability at high speed, and resistance to harsh environments are difficult to achieve using aluminum or cast-iron guideways with mechanical bearings. The HC-90’s ceramic column and runs on LK Metrology’s proprietary air suspension system to deliver Bridge-like accuracy for larger components.

- High-quality 96% Alumina Ceramic for optimal speed, stiffness and long-lasting measurement accuracy

- Designed for production-line integration

- Flexible positioning and articulation

- Four design options

HC-90TTable-mounted single arm guideway

|

HC-90RSingle arm guideway

|

HC-90TRTwin arm guideway

|

HC-90WTRFloor-integrated twin guideway

|

Probing Options

Tactile Probes

Multi-sensor

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

Aluminum Horizontal CMM

An advanced design for cost-effective dimensional inspection of large components typical of the automotive, land transport and heavy industries.

- Single or double arm configurations Designed for production-line integration

- Air bearings on the YZ axes,

- Double recirculating bearing guideways on the X-axis

- Optional cast iron work-plates and loading/unloading systems

- Protective covers to ensure thermal and contaminant insulation

- Simplified manual or automated part loading and unloading

Probing Options

Multi-sensor

|

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

LY-90R – Runway-based horizontal CMM

The LY-90R is a runway-based CMM designed for part accessibility. Developed specifically for automotive, land transport and heavy industry quality inspection applications, the LY-90R can be installed on a pneumatic vibration isolation system for use in production environments, without the need for dedicated foundations for the system

- Runway horizontal arm CMM

- Measurement system with linear optical transducers

- Control of movement through servo motors

- Air bearings on the Y-Z axes, precision guideways on the X-axis

- Mechanical carrier counterbalance with safety brake

- Optional cast iron work-plates

LY-90T – Table-mounted horizontal CMM

The LY-90T is a table CMM designed for part accessibility. Developed specifically for car-body and sub-assembly quality inspection applications, the LY-90T is the perfect solution for sheet-metal and plastic component metrology.

- Console-mounted horizontal arm

- Measurement system with linear optical transducers

- Control of movement through servo motors

- Air bearings on the Y-Z axes and precision guideways on the X-axis

- Mechanical carrier counterbalance with safety brake

- Optional cast iron work-plates

Probing Options

Multi-sensor

|

Touch Triggers

|

|

Laser Scanning

|

|

|

|

SOFTWARE

LK Metrology offers a range of multi-sensor CMM software packages to control and gather measurement data.

Metrology Software for Industry 4.0

CAMIO is a highly customizable software package that allows manufacturers to harness the full pothential of their in-line CMMs without spending a fortune on software development. Designed from the ground up to easily control, gather data, and automate almost any CMM, CAMIO comes with a full Industry 4.0 toolset to increase your metrology quality, accuracy, and throughput and allows you to build interoperable inspection workflows, reports, virtual assemblies, and much much more.

- Automated inspection software

- Fully programmable

- Built for engineers and operators

Optional software modules

CAMIO Gear – to measure helical gears, spur gears, partial gears, inner and outer gears…

CAMIO Blade – point cloud blade inspection software module for airfoils and blades (aerospace and energy)

CAMIO SPC – to automate statistical process control

CAMIO Point Cloud – for point cloud inspection

Full-featured dimensional metrology software

ARCOCAD is a full-featured dimensional metrology application that controls, gathers data, and automates CMM processes. Built to optimize accuracy, measurement speed, and programability, ARCOCAD drives CMM hardware and gathers measurement data producing detailed inspection reports and graphical representations.

- Designed for Industry 4.0 metrology

- Fully programmable

- Integrated with Metrology Gate

Optional software modules

ARCO Gear – to measure helical gears, spur gears, partial gears, inner and outer gears…

ARCO Blade – point cloud blade inspection software module for airfoils and blades (aerospace and energy)

ARCO SPC – to automate statistical process control

ARCO Point Cloud – for point cloud inspection

Machine Monitor

Keep track of your machines from your mobile app or your web browser.

Have the full status under control: the program running, environmental information and the history of the hardware errors.

A single dashboard will always keep you updated.

Statistical Evaluation

All the measuring results stored in a single repository accessible anytime and everywhere.

A full statistical evaluation of the data lets any user understand how the production is going without going through desktop application, justdownload the app to always be connected

Comparative Analysis

Get an analytic analysis of the measuring results comparing the different machines and measuring tools production in order to get a view

of the performance.

This is a fundamental help to plan your next maintenance or a help in choosing the next machine tool.

Metrology Power with Simplicity

TouchDMIS combines the power required for advanced users with the simplicity needed for new users, making measurement capability easily accessible from the CAD room to the production floor.

TouchDMIS, in its 3rd iteration of CMM software, has taken on the mission of creating a user interface that intuitively leads the user through the basic measurement process.

Software that Simplifies Your CMM

The intuitive interface of TouchDMIS has been ergonomically designed to provide maximum productivity for both novice and expert CMM users.

TouchDMIS has no drop-down menus or stacked toolbars with all functionality accessed with just a touch of your finger.

Maximize Your Productivity

TouchDMIS requires just a few hours of training and offers an incredibly short learning curve.

The software can be operated entirely via touchscreen, using intuitive touch, swipe, and gesture commands.

Create Reports

TouchDMIS offers a choice of inspection reports for Real-time reporting.

XML, Excel, TXT, and PDF exportable output provides flexible reporting.

Applications Typical for TouchDMIS

TouchDMIS metrology software is often used in the following applications

- Inspection

- Reverse Engineering

- Part Archiving

- Rapid Prototyping

- Engineering Analysis

PolyWorks|Inspector™ is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

CMM-Manager by QxSoft is a task-oriented, highly intuitive, 3D CAD based, software package for any CMM. Software is available for both new and existing CMM hardware. We offer software for vision, manual, portable, and CNC coordinate measuring machines. Avoid costly hardware retrofits, our software connects directly to your existing CMM or Metrology equipment by plug-n-play retrofit.

Renishaw’s new MODUS™ CMM software application enables it to offer CMM users a complete retrofit upgrade, supplied and supported by Renishaw. With full support for its entire range of sensors, including the award-winning REVO®, MODUS™ provides a powerful platform for 5-axis measurement.

MODULES

SENSORS

Our multi-sensor CMMs can be equipped with an extensive range of scanning and trigger contact sensors and optical scanning sensors, tool changing automation hardware and probe heads.

VIVID SLK20

High accuracy, high resolution blue laser CMM scanner

Thanks to VIVID laser scanner technology from LK Metrology, the SLK20 provides quality professionals with an opportunity to maximize efficiency when measuring complex surfaces, small details, fragile parts, dark materials and reflective surfaces – by overcoming the limitations of tactile inspection and other non-contact technologies.

VIVID Technology

VIVID multiple exposure technology quadruples the dynamic range of the laser scanner. More surfaces, including the most challenging dark, transparent or highly reflective materials can be measured in a single pass or the laser scanner. Phasing the exposure time during scanning to match the part surface, optimizes acquisition speeds and data quality. Exposure settings are included for typical applications, with fully configurable user settings for individual requirements.

| Scanner Type | Line |

| Laser line width | 24 mm (.95 in) |

| Points/second | 268k |

| Resolution (near, mid, far) | 9.3, 10.9, 12.9 µm |

| Scan Rate | 140 Hz |

NIKON L100

The newest laser scanner introduces the 4th generation Enhanced Sensor Performance (ESP4). With a high point resolution along a 100 mm wide stripe, the L100 achieves a data collection rate of 200,000 points per second. As the most productive line scanner, it offers double the point resolution, 2.5 x the scanning speed and 30% better accuracy than other scanners. With a projected field-of-view, the L100 makes for easy path planning and the ESP4 means it is the most adept at handling difficult shiny or reflective surfaces. Like other line scanners, the L100 is often used for surface and feature inspection in automotive and aerospace applications. However, its specification makes it the fastest and most accurate multi-purpose scanner, therefor the most proficient tool for almost any application.

| Scanner Type | Line |

| Laser line width | 100 mm (3.9 in) |

| Points/second | 200k |

| Resolution | 42 µm |

| Standoff | 135 |

NIKON LC15Dx

The high accuracy laser scanner LC15Dx features a small laser line, and a higher number of points along said line for a higher resolution, to make it the most accurate laser scanner available on the market today. The LC15Dx perfectly suits digitizing compact or detailed objects with higher point density and tighter tolerances, both suited for surfaces and features. Considering this, the LC15Dx is often used for the inspection of high precision parts. The LC15Dx closes the gap between laser scanner and tactile probe accuracy, making it a viable alternative to a tactile probe for an increasing number of high precision CMM applications. In tests, the LC15Dx achieved the accuracy associated with using a tactile probe on a CMM. The probing error of 1.9 µm mirrors the accuracy expected when using a CMM fitted with a tactile probe. Unlike a tactile probe though, the LC15Dx uses non-contact 3D laser triangulation to measure the surface directly and eliminate probe compensation errors.

| Scanner Type | Line |

| Laser line width | 15 mm (0.6 in) |

| Points/second | 70k |

| Resolution | 22 µm |

| Standoff | 68 |

NIKON XC65Dx

The XC65Dx Cross Scanner utilizes three laser stripe scanners in one sensor. The three lasers are spaced 120 degrees apart and observe the part in question from three angles. By doing this, the XC65Dx can acquire the same amount of data with just one scan than a line scanner would do in three scans. This feature makes the XC65Dx well suited to feature inspection of slots, holes and grooves in sheet metals or items with a large complex surface area. It is often used in automotive BIW (Body-in-White) inspection, gap & flush and driveline casting inspection. Whilst the long standoff Cross Scanner retains the many advantages of the original XC65Dx, it also excels in dealing with accessing difficult-to-reach or obscured areas. By capturing geometries up to a distance of 170 mm (7.1”), the scanner gains optimum access to cavity surfaces of body-in-white structures or can scan over the clamps that hold components in position. For these reasons, the XC65Dx-LS scanner is used a lot on horizontal-arm CMM in the automotive industry.

| Scanner Type | Cross |

| Laser line width | 3x 65 mm (2.6 in) |

| Points/second | 75k |

| Resolution | 65 µm |

| Standoff | 107/202 |

A range of fixed and manually adjustable heads that connect a touch-trigger probe to the machine quill, allowing flexible inspection of complex components.

Manual Indexing

MH20i – Indexable head for use with TP20 stylus modules

Manual indexable probe head that combines the TP20 kinematic stylus module mount with two axis indexing, enabling flexible stylus changing and repeatable probe re-orientation.

| Head Type | Manual Indexing |

| Head Positions | 168 |

| Angular Tilt | 0o to +90o in 15o steps |

| Angular Rotation | ±180o in 15o steps |

| Touch Probe | Integral |

PH6 – Fixed head with one probe socket

The PH6 is a small diameter, vertical probe head with one M8 thread probe mount for a single probe, with an integral cable.

- Compatible with M8 probes

- Shank mounted

- Simple to install

| Head Type | Fixed (Vertical) |

| Head Positions | – |

| Angular Tilt | – |

| Angular Rotation | – |

| Touch Probe | TP20, TP200 |

PH6M – Fixed head with autojoint

The PH6M is compatible with multi-wired probes TP7M, OTP6M and SP600M, as well as the complete Renishaw probe range through the use of the PA series of adaptors.

| Head Type | Fixed (Vertical) |

| Head Positions | – |

| Angular Tilt | – |

| Angular Rotation | – |

| Touch Probe | TP20, TP200, SP25M |

Renishaw probe systems are available in a wide variety of types to

enable a best match for a particular application

Motorized Head Systems

Motorized heads enable automated, repeatable re-orientation of probes to allow access to features on all faces of the part, improving the capability of the CMM and maximizing productivity.

PH10T PLUS

The PH10T PLUS is similar to the PH10M PLUS, except that it features an M8 thread probe mount in place of the autojoint. All M8 threaded probes, such as TP20 and TP200, and extension bars fit directly onto the head. The PH10T PLUS is fully compatible with all of Renishaw’s stylus and module change systems.

| Head Type | Motorized Indexing |

| Head Positions | 720 |

| Angular Tilt | 0o to +105o in 7.5o steps |

| Angular Rotation | 0o to ±180o in 7.5o steps |

| Touch Probe | TP20, TP200 |

PH10M PLUS

The PH10M PLUS can carry long extension bars and complex probes such as SP25M or TP7M. The highly repeatable autojoint allows rapid probe or extension bar changing without the need for re-qualification.

| Head Type | Motorized Indexing |

| Head Positions | 720 |

| Angular Tilt | 0o to +105o in 7.5o steps |

| Angular Rotation | 0o to ±180o in 7.5o steps |

| Touch Probe | TP20, TP200, SP25M |

| Laser Scanner | LC15Dx, LC60Dx, L100, C65Dx/LS, VIVID SLK20 |

PH10MQ PLUS

The PH10MQ PLUS is a variant of the PH10M PLUS that allows the motorised head to be attached directly to the quill with the B-axis of the head inside the quill itself.

| Head Type | Indexing Head |

| Head Positions | 720 |

| Angular Tilt | 0o to +105o in 7.5o steps |

| Angular Rotation | 0o to ±180o in 7.5o steps |

| Touch Probe | TP20, TP200, SP25M |

| Laser Scanner | LC15Dx, LC60Dx, L100, C65Dx/LS, VIVID SLK20 |

PHS-2

Servo Head – PHS-2 is designed to meet the arduous requirements of ‘body-in-white’ measurement, where fine angular position and long reach are needed.

| Head Type | 5-Axis Wrist |

| Head Positions | Infinite |

| Angular Tilt | -184o to 184o in 1µm steps at 100mm radius |

| Angular Rotation | -184o to 184o in 1µm steps at 100mm radius |

| Touch Probe | TP20, TP200, SP25M |

| Laser Scanner | LC15Dx, LC60Dx, L100, C65Dx/LS, VIVID SLK20 |

Touch-Trigger Probe Systems

Touch-trigger probes measure discrete points, making them ideal for inspection of 3-dimensional geometric parts.

TP20

Compact module changing touch-trigger probe, which allows the use of a range of stylus configurations and extensions to access features on complex parts.

| Probe Type | Touch Trigger |

| Min. stylus diameter | 0.3 (0.012) |

| Max. stylus diameter | 60 (2.4) |

| Max. probe extension | 300 (11.8) |

| Min. probing force | 0.055 N |

TP200

A compact, module-changing probe that uses strain-gauge mechanisms for higher accuracy and longer life than kinematic touch-trigger probes.

| Probe Type | Touch Trigger |

| Min. stylus diameter | 0.3 (0.012) |

| Max. stylus diameter | 100 (3.9) |

| Max. probe extension | 300 (11.8) |

| Min. probing force | 0.02 N |

Scanning Probe Systems

Scanning probes can acquire several hundred surface points each second, enabling measurement of form as well as size and position.

SP25M

At only 25 mm in diameter, and with a range of scanning and touch-trigger modules, the SP25M is the world’s most compact and versatile scanning probe system.

| Probe Type | Scanning |

| Min. stylus diameter | 0.5 (0.02) |

| Max. stylus diameter | 400 (15.7) |

| Max. probe extension | 100 (3.9) |

| Min. probing force | 0.1 N |

SP80

Combining long stylus reach with ultra-high accuracy performance, SP80 is the first-choice scanning probe for many applications.

| Probe Type | Scanning |

| Min. stylus diameter | 0.3 (0.012) |

| Max. stylus diameter | 1000 (39.4) |

| Max. probe extension | – |

| Min. probing force | 2.2 N |

Unlike conventional CMM measurement methods, Renishaw’s 5-axis technology uses the synchronized motion of the CMM and the head axes to

minimize the machine’s dynamic errors at ultra‑high measuring speeds.

REVO

5-Axis Measurement System

A REVO® system delivers high performance scanning, non-contact inspection and surface finish analysis on a single CMM

High-speed measurement

- Up to 500 mm/sec resulting in increased part throughput

- Data collection rates up to 4,000 points per second

- Infinite positioning and 5-axis motion reduces non-productive transitions between features

- Rapid calibration with all positions inferred means more time measuring

High system accuracy

- 5-axis scanning minimises CMM motion and the associated dynamic errors

- Stylus wear minimised by extremely low scanning forces

- Infinite positioning and five-axis motion aid access to difficult features

- Tip-sensing further adds to the systems’ accuracy and flexibility

Great flexibility

- Maximum reach up to 800 mm from centre of head rotation

- Multi-sensor probe and stylus changing capability

- Renishaw UCCserver software application (based on I++ DME command protocol) provides the interface for REVO-2 control

- The removable probe system, used in conjunction with a low cost changer, provides added system flexibility

RSP2 -RSP2 is a dedicated lightweight tip-sensing probe for use on REVO systems, capable of 2D-scanning (x, y) and 3D-touch trigger measurement.

RSP3 – The RSP3 range complements the RSP2 probe, providing the REVO system with 3D-scanning (x,y,z) and crank stylus capabilities. It is used for

3-axis scanning, such as with a fixed REVO head angle during measurement.

| Head Type | Fixed Head |

| Head Positions | Infinite |

| Angular Tilt | -100o to +120o |

| Angular Rotation | Continuous |

| Touch Probe | RSP2, RSP3 |

PH20

Unlike conventional touch-trigger measurement methods which rely on speeding up the motion of the CMM’s 3 axes to measure quickly, PH20 utilizes the head motion technology developed for

the multi-award winning REVO system to minimize the dynamic errors of the CMM at higher measurement speeds.

PH20’s unique ‘head touches’ allow measurement points to be taken by moving only the head, rather than the CMM structure. Points can be taken faster, and with improved accuracy and repeatability.

Furthermore, 5-axis motion eliminates time spent indexing the head. Together these speed increases typically result in a 3-fold improvement in throughput over conventional systems.

| Head Type | 5-Axis Continuous |

| Head Positions | Infinite |

| Angular Tilt | ±115o |

| Angular Rotation | Infinite |

| Touch Probe | Integral |

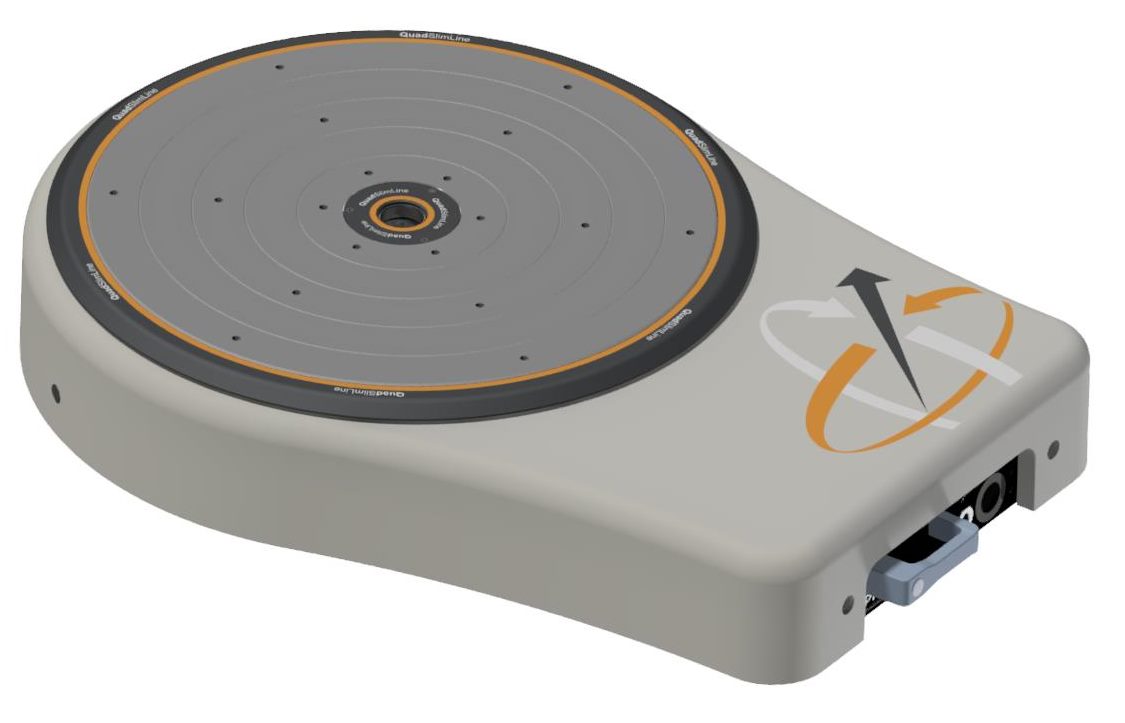

Accessory Name

PORTABLE MEASURING ARMS

Take your CMM with you to any location with our portable measurement solutions. Our portable solutions allow you to perform rapid, battery-operated measurements where the operator can move freely around the part being measured.

Portable productivity, practicality, and flexibility

Equipped with Wi-Fi connectivity, complete battery operation, and a mobile workstation, the FREEDOM ARM gives you total mobility for your metrology needs.

With 6 axis and 7 axis portable measuring arms – for quality control, on-machine verification, reverse engineering or 3D modelling, the FREEDOM ARM series features three accuracy levels and several sizes in different portable arm configurations. These can be enhanced with manual-moving rotary tables, touch probes, and laser scanner options.

Designed for productivity, practicality, and flexibility, LK Metrology’s FREEDOM ARM performs challenging metrology tasks in almost any manufacturing environment.

- Go-to Measurement Where It Benefits You Most …

- Touch Probe

- 6-axis

- Laser Scanner & Touch Probe

- 7-axis

Accessory Name

Contact Us

If you have any questions about our products or services or would like to book a demonstration, don't hesitate to get in touch with LK Metrology using this form.